Additive Manufacturing (AM)

Dai-ichi Ceramo has been developing PIM feedstock to create small complicated precision components made from metal or ceramic powders over many years.

We are now applying the accumulated technology to additive manufacturing (AM) using 3D printers that allows creation of certain geometric shaped metal/ceramic components which were not possible to make by conventional technologies.

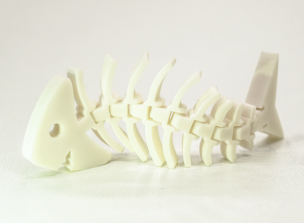

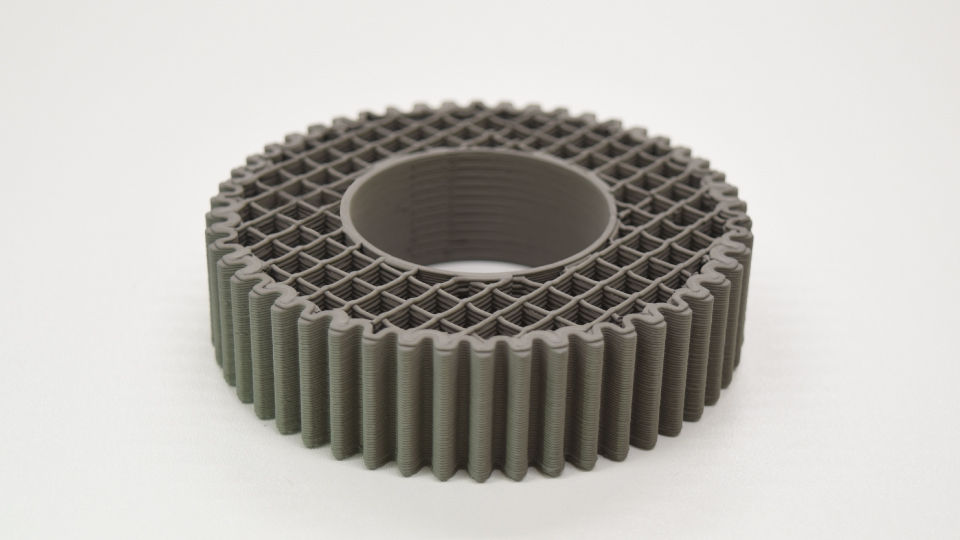

AM application example

In this image, the gear-shaped object has an internal lattice structure the hollowness percentage of which is intentionally changeable depending on the design.

This sort of structure having a space or cavity inside can achieve weight reduction effectively while retaining the maximum permissible mechanical strength required for metal or ceramic components.