Dispersion mixers

Blended powder is mixed with a specific amount of binder material in a dispersion mixer at an elevated temperature until the powder particles are uniformly coated with the binder. The obtained compound has exceptional uniformity.

We have a continuous and complete production system from R&D to final inspection via prototype designing, testing and production. Our plant is fully equipped with different-sized dispersion mixers whose mixing volume capacities range from 3 to 35 L per batch to meet customer needs.

Multiple production lines that are divided to prevent cross contaminations

Smaller batch sizes also available on the initial testing phase as per requirement.

We technically assist your product development through PIM processing e.g. mixing, molding, debinding, sintering and analysis in small batches.

Our plant is equipped with multiple dispersion mixers the volume capacities of which are 20 and 30 liters per batch.

The production lines/areas are divided and separated so that no cross contamination occurs.

Blended powder is mixed with a specific amount of binder material in a dispersion mixer at an elevated temperature until the powder particles are uniformly coated with the binder. The obtained compound has exceptional uniformity.

Compound is directly charged to a pelletizer from the dispersion mixer to make uniform pellets through a cutting process. These pellets are called feedstock.

We have multiple dispersion mixers, the volume capacities of which are varied from 30 cc to 3 L per batch, to suit each customer’s requirement to either test or develop new materials.

Mixing

Pelletization

Injection molding

Debinding

Sintering

Injection molding machine

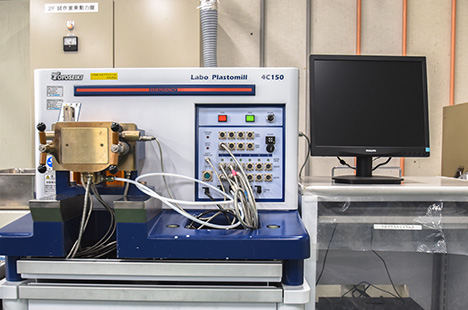

Laboratory mixer

We have a wide range of testing and analysis equipment for contract (OEM) manufacturing and custom development for customers.

Capillary rheometer flowtester, Thermal analyzer (TG-DTA), Laser particle size distribution analyzer, Specific surface analyzer, Scanning electron microscopes(SEM)