PIM

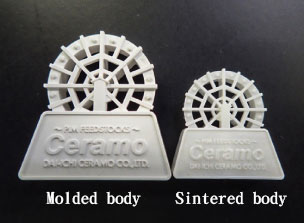

Powder Injection Molding (PIM), including Metal Injection Molding (MIM) and Ceramic Injection Molding (CIM), is a near-net-shape processing method suitable for producing precise and complex metal or ceramic components.

It can mass-produce high-precision and high-density products with accuracy of ± 0.5% or less and relative density of 95% or more.

Flowability

Good flowability for stable molding process

Degreasing

Readily-decomposable binder formulations

Low contamination

Low contamination by compounding technology

Recyclability

Good recycling characteristics

Metal feedstock (MIM)

Feedstock for metal powder injection molding (MIM)

We develop a variety of metal alloys and magnetic material products as well as typical metals such as iron and stainless steel.

| DM316L-3000 series | DM630-3100 series | |

|---|---|---|

| Raw material powder | SUS316L | SUS630(17-4PH) |

| Additive amount | 6.6 wt% / 36.4 vol% | 7.0 wt% / 37.1 vol% |

| Linear shrinkage (calculated value) | 14% | 14% |

| Molding temperature | 160-180°C | 160-180°C |

| Relative density | 97% TD | 97% TD |

| * Above data are typical values, not specifications. | ||

Ceramics feedstock (CIM)

We can propose optimal raw materials that meet your target application

and conditions such as zirconia, high purity alumina, silicon carbide, aluminum nitride and so on.

| High purity alumina | Zirconia (suitable for structures) | Zirconia (suitable for ferrules) | |

|---|---|---|---|

| DA-series | DZ-series | DZF-series | |

| Raw material powder | AI2O3 | ZrO2-3.0Y | ZrO2-3.2Y |

| Additive amount | 16.0 wt% / 42.6 vol% | 16.0 wt% / 53.2 vol% | 18.0 wt% / 55.2 vol% |

| Linear shrinkage (calculated value) | 17% | 22% | 23% |

| Molding temperature | 160-180°C | 160-180°C | 160-190°C |

| Characteristics | Electrical insulation, abrasion resistance, chemical stability | Strength, toughness | Strength, toughness, hydrothermal deterioration resistance |

| * Above data are typical values, not specifications. | |||